Graphite Electrodes

In the steelmaking process, iron scrap gets melted in an electric arc furnace and recycled. Graphite electrodes, a kind of conductor, are an essential component in this kind of furnace. They can melt scrap at a temperature of about 1600℃.

What are Graphite Electrodes?

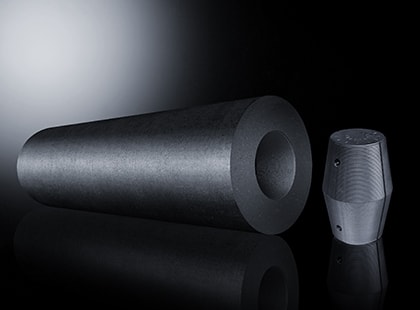

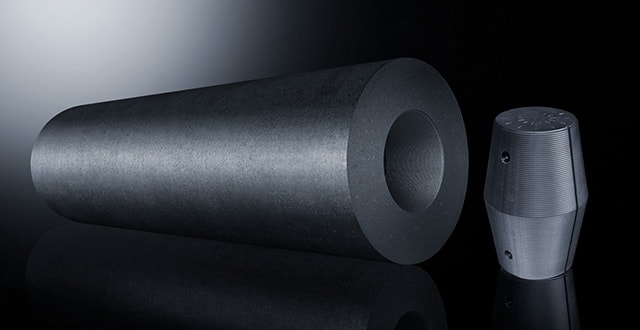

Did you know that there are two ways to make iron? The blast furnace method and the electric arc furnace method. The electric arc furnace method recycles used iron scrap by melting it in an electric arc furnace. It is the graphite electrodes inside the furnace that actually melt the iron. Graphite has high thermal conductivity and is very resistant to heat and impact. It also has low electrical resistance, which means it can conduct the large electrical currents needed to melt iron. In recent years, graphite electrodes have been made even more efficient: they can now conduct even higher currents and more power. Using the expertise collected over a century of innovation, Tokai Carbon has developed the world's biggest electrodes. They measure 32 inches (about 80 cm) in diameter and are 3 meters long. Tokai Carbon's graphite electrodes are made to last, making them a trusted name in the industry.

Applications

Iron and Steel Products

Recycled iron and steel are used in a wide range of industries and products.

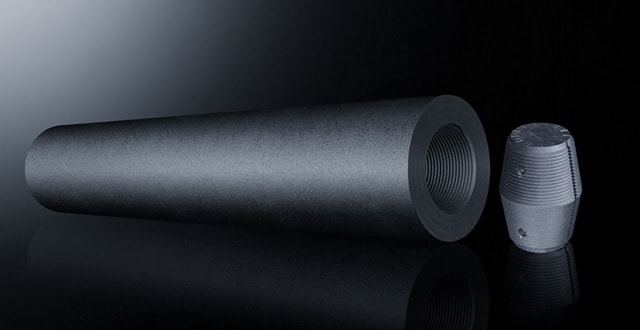

Graphite Electrodes Varieties

For DC Furnaces (direct current furnaces) / Size: 22-32 inches

Electrodes for DC furnaces, which require 1 column of graphite electrodes. High maximum current density. The diameter of these electrodes is getting bigger: the current maximum diameter is 32 inches (800 mm).

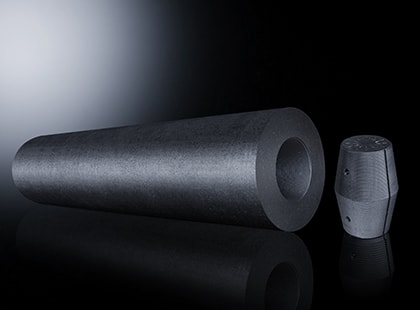

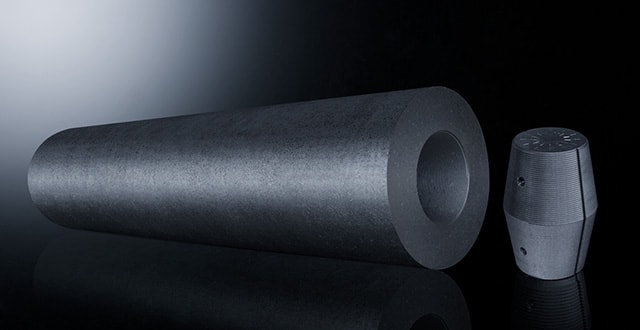

For AC Furnaces (alternating current furnaces) / Size: 16-28 inches.

Alternating current furnaces require 3 columns of graphite electrodes. They mostly use 20-28 inch electrodes, the standard size in electric furnaces.

For LF Furnaces (refining furnaces) / Size: 10-18 inches

These electrodes are for refining materials like molten steel. LF Furnaces have a smaller capacity than DC.

Guide to Graphite Electrodes

Scroll horizontally to view the whole table

| Unit | AC Furnace | DC Furnace | |||

|---|---|---|---|---|---|

| 350~450mm 14"~18" |

500~700mm 20"~28 |

550~800mm 22"~32" |

|||

| Features | RP | UHP | UHP | UHP | |

| Bulk density | g/cm3 | 1.58~1.70 | 1.65~1.76 | 1.66~1.74 | 1.68~1.75 |

| Specific resistance | μΩm | 6.0~8.5 | 4.5~6.5 | 4.5~6.5 | 4.2~5.5 |

| Young's modulus | kN/mm2 | 8~12 | 11~16 | 9~14 | 9~13 |

| GPa | 8~12 | 11~16 | 9~14 | 9~13 | |

| kgf/mm2 | 800~1,200 | 1,100~1,650 | 950~1,400 | 900~1,300 | |

| Bending strength | N/cm2 | 1,000~1,400 | 1,200~1,800 | 1,000~1,500 | 1,000~1,500 |

| MPa | 10~14 | 12~18 | 10~15 | 10~15 | |

| kgf/cm2 | 100~140 | 120~180 | 100~150 | 100~150 | |

| Thermal expansion coefficient (R.T. to 400°C) |

×10-6/゚C | 0.8~1.5 | 0.8~1.5 | 0.5~1.0 | 0.5~0.9 |

| ×10-6/゚F | 0.4~0.8 | 0.4~0.8 | 0.3~0.6 | 0.3~0.5 | |

| True density | g/cm3 | 2.20~2.23 | 2.20~2.23 | 2.20~2.23 | 2.20~2.23 |

| Total porosity | % | 23~29 | 20~26 | 21~26 | 20~25 |

| Ash content | % | Less than 0.2 | Less than 0.2 | Less than 0.2 | Less than 0.2 |

Size/Weight Chart

Scroll horizontally to view the whole table

| Name | Pole diameter | Pole length | Pole weight (reference value) | |||

|---|---|---|---|---|---|---|

| Diameter x length | Maximum | Minimum | Maximum | Minimum | Pole product weight (excluding nipple) | |

| inch | mm | mm | mm | mm | mm | kg |

| 14×60 | 350×1500 | 357 | 352 | 1550 | 1400 | 253 |

| 14×72 | 350×1800 | 1875 | 1700; | 304 | ||

| 14×96 | 350×2400 | 2475 | 2275 | 406 | ||

| 16×60 | 400×1500 | 409 | 403 | 1550 | 1400 | 334 |

| 16×72 | 400×1800 | 1875 | 1700 | 395 | ||

| 16×96 | 400×2400 | 2475 | 2275 | 532 | ||

| 18×72 | 450×1800 | 460 | 454 | 1875 | 1700 | 496 |

| 18×96 | 450×2400 | 2475 | 2275 | 665 | ||

| 18×110 | 450×2700 | 2850 | 2550 | 766 | ||

| 20×72 | 500×1800 | 511 | 505 | 1875 | 1700 | 614 |

| 20×84 | 500×2100 | 2175 | 1975 | 715 | ||

| 20×96 | 500×2400 | 2475 | 2275 | 824 | ||

| 20×110 | 500×2700 | 2850 | 2550 | 927 | ||

| 22×84 | 550×2100 | 562 | 556 | 2175 | 1975 | 873 |

| 22×96 | 550×2400 | 2475 | 2275 | 995 | ||

| 24×84 | 600×2100 | 613 | 607 | 2175 | 1975 | 1040 |

| 24×96 | 600×2400 | 2475 | 2275 | 1190 | ||

| 24×110 | 600×2700 | 2850 | 2550 | 1340 | ||

| 26×110 | 650×2700 | 663 | 657 | 2850 | 2550 | 1580 |

| 28×110 | 700×2700 | 714 | 708 | 2850 | 2550 | 1830 |

| 30×110 | 750×2700 | 765 | 759 | 2850 | 2550 | 2060 |

| 32×110 | 800×2700 | 816 | 810 | 2850 | 2550 | 2450 |