Business Models of Graphite Electrode Division Quick Look Graphite Electrode Business

Needle coke Needle-like crystals develop.

Low thermal expansion coefficient.

Pitch Produced by heat treatment of coal tar.

Carbonizes under heat (50% yield).

Needle coke and pitch are mixed and then molded. Heat treatment is then applied in the baking and graphitization process to form the finished product.

Kneeding/extrusion baking

Primary baking

(1 months)

Pitch impregnation

(Few days)

Secondary baking

(2 to 4 weeks)

Graphitization - Machining

Finished product - Shipping

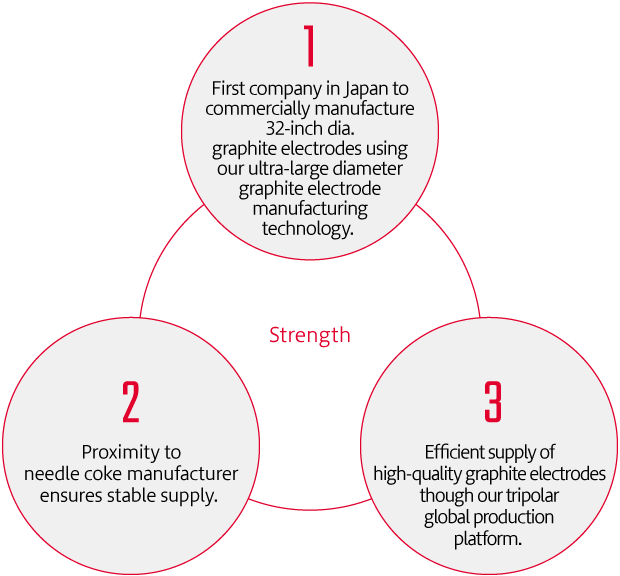

Manufacturing site in Japan, Germany and in North America

Reach customers worldwide with tripolar structure in Asia, Europe and North America.

Head Office (Tokyo), overseeing global sales

Sales and technical service network covering all of Europe and the Americas.

Steel manufacturers

(electric arc furnace steelmaking)