Industrial Furnaces and Related Products

Industrial furnaces and related products used for heat treatment of ceramics, electronic components, metals, glass and more. Produced and sold by group company Tokai Konetsu Kogyo Co., Ltd.

What are EREMA (silicon carbide) Heating Elements and Industrial Furnaces?

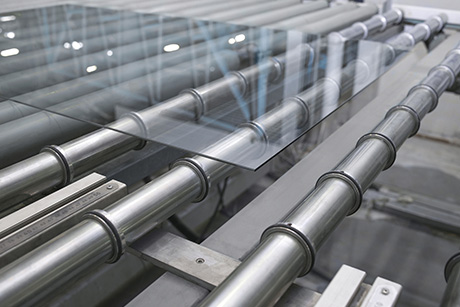

The flat glass used in smartphone liquid crystal screens is made in a gas or oil furnace. It comes out of the furnace very hot and needs to be cooled down slowly. EREMA heating elements are responsible for that delicate temperature regulation. In 1927, EREMA became the first silicon carbide heating elements to be sold commercially in Japan. We have been improving their quality ever since and are now the biggest producer in the industry. Industrial furnaces are used to heat, melt and sinter glass, ceramics, electronic components, metals and powders. As a comprehensive manufacturer, we design and manufacture industrial furnaces as well as the heating elements and refractory materials that go in them. From small test furnaces to large scale industrial equipment, we enlist a wide range of technologies to produce furnaces and related products for all fields.

Applications

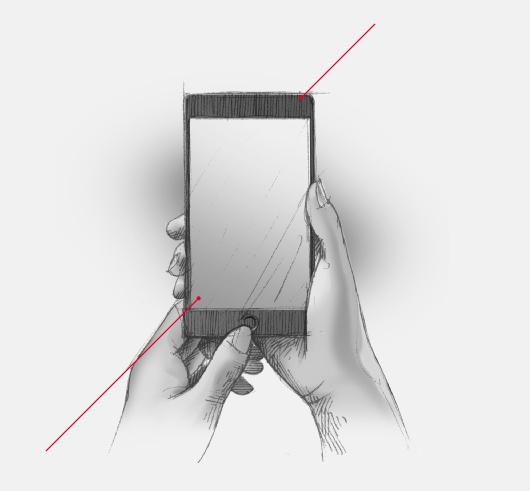

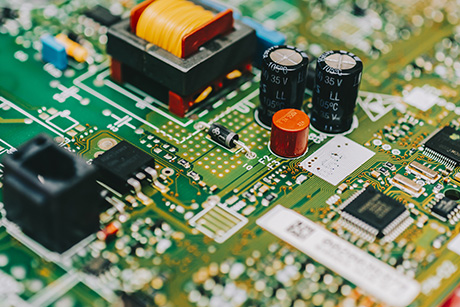

Flat Screens/Electronic Parts

EREMA (silicon carbide) heating elements are used to heat electric furnaces for the heat treatment of glass, electronic parts, lithium-ion batteries and much more.

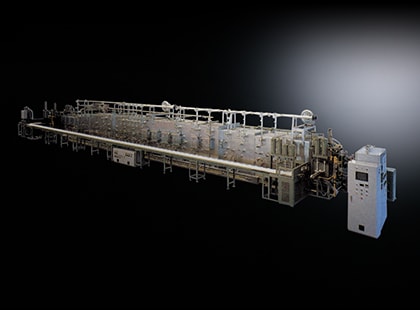

Cases/Electronic Parts

Tokai Carbon's industrial furnaces are used as electric furnaces for the heat treatment of electronic parts, lithium-ion batteries and more.

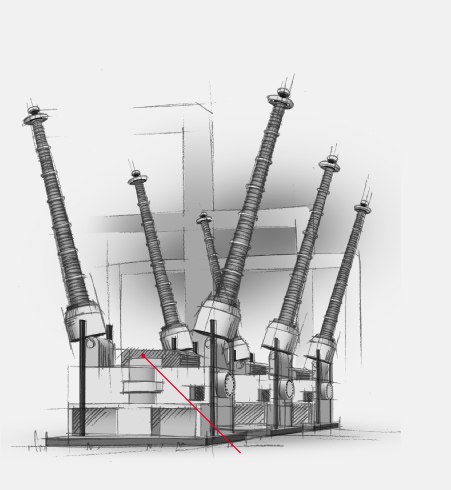

Power Plants

EREMA resistors are used in large circuit breakers and all kinds of heavy electric machinery.

Industrial Furnaces and Related Products Varieties

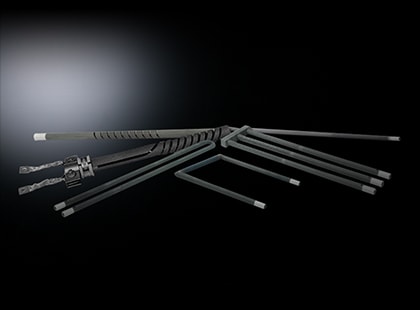

EREMA (silicon carbide) Heating Elements

- ・Can withstand a surface temperature of 1500°C (or 1600°C for SG and SGR models).

- ・High heat generation capacity per unit area. 5 to 10 times that of Nichrome heating elements.

- ・Strong, durable and chemically stable.

- ・A heat source that does not cause air or noise pollution.

- ・Available with a variety of coatings to withstand steam and noxious gas.

- ・Easy to handle.

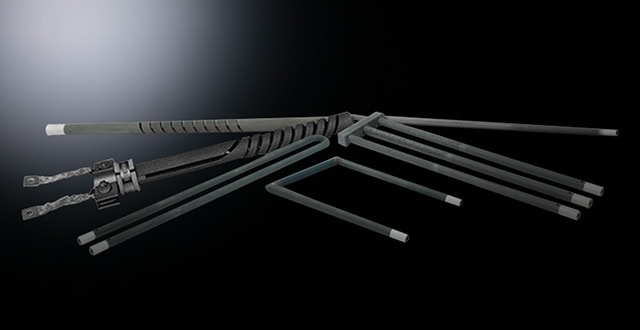

EREMA Resistors

- ・Coil-free. Non-inductive.

- ・Do not snap. Very reliable.

- ・Very resistant to high voltage. Small in size but can handle high power.

- ・Can withstand high temperatures. Thermally and chemically stable.

- ・Can be used in water, steam and oil.

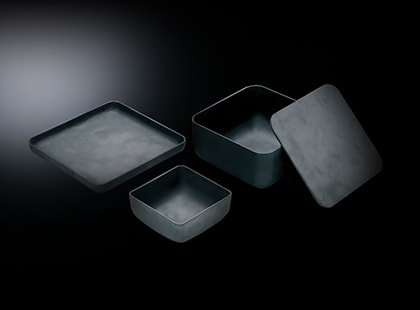

Recryte SiC Structural Materials

We combined the manufacturing technology behind EREMA heating elements with the SiC-related know-how we have gathered over the years to develop this ceramic structural material, which can withstand high temperatures and has high thermal conductivity.

- ■Hanging Bars RS900 group / Support Bars RS900 group / Beams RS900 group

- ■Boards (Setter) [Types] RS420, RS230, RS1000

*Available up to 300 x 7t - ■Other jigs [Types] RS420, RS230, RS900 etc.

Materials can be selected for specific requirements.

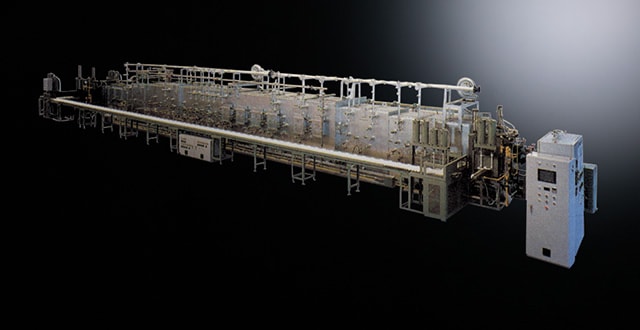

Industrial Furnaces

We custom manufacture all our industrial furnaces. In our design process, we insist on the following.

- ・We select and computerize factors such as temperature, atmosphere and pressure appropriate to the product processing software.

- ・We endeavor to automize product insertion and removal and to save on energy and space.

- ・We prioritize safe design.